In today’s rapidly evolving industrial landscape, automation integrators play a crucial role in optimizing manufacturing processes and driving operational efficiency. These professionals possess the expertise to seamlessly integrate advanced technologies into existing production systems, enabling businesses to stay competitive in an increasingly automated world.

Enhancing Efficiency and Productivity

Automation integrators are adept at identifying areas within the manufacturing process that can benefit from automation. By leveraging their knowledge of cutting-edge technologies and industry best practices, they can design and implement solutions that streamline operations, reduce manual labor requirements, and enhance overall productivity.

Through the integration of robotics, artificial intelligence (AI), machine learning algorithms, and other innovative tools, automation integrators enable manufacturers to achieve higher levels of precision, accuracy, and speed. This not only leads to improved product quality but also allows for increased output capacity without compromising on safety or reliability.

Solidot Electronic Technology: A Leading Automation Integrator

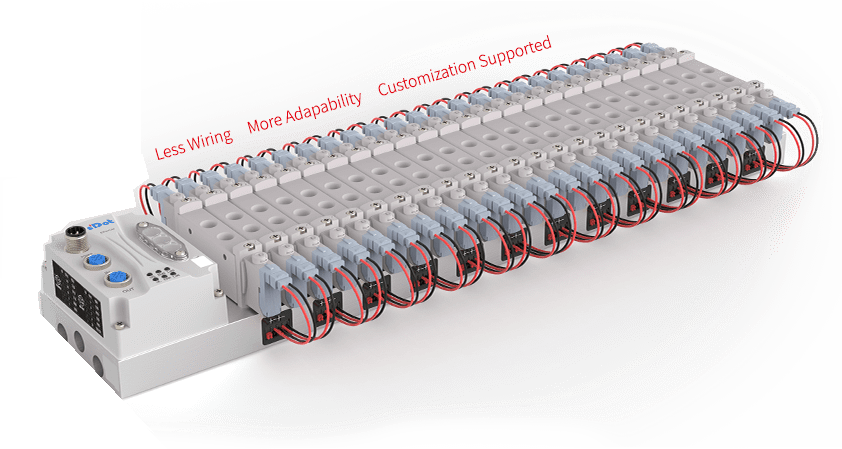

One notable player in the field of automation integration is Solidot Electronic Technology. With years of experience serving diverse industries such as automotive manufacturing, electronics assembly, pharmaceuticals production, and more; Solidot has established itself as a trusted partner for companies seeking comprehensive automation solutions.

By collaborating closely with clients throughout every stage of a project – from initial consultation to system implementation – Solidot ensures that all unique requirements are met effectively. Their team of skilled engineers possesses deep domain knowledge across various disciplines like control systems engineering, electrical design & installation services; allowing them to deliver tailored solutions that address specific challenges faced by manufacturers.

The Advantages of IO-Link to PROFINET Integration

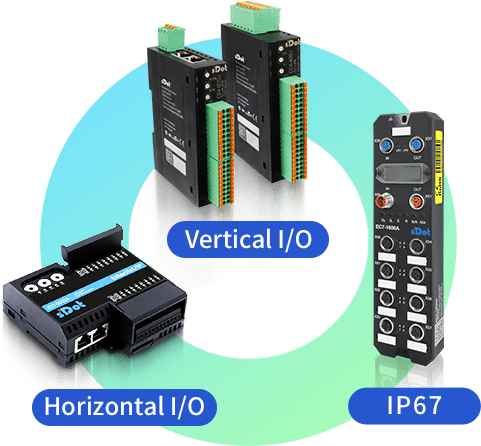

An emerging trend within the realm of automation integration is the adoption of IO-Link technology integrated with PROFINET. IO-Link is a standardized communication protocol that enables seamless connectivity between sensors, actuators, and other devices within the manufacturing environment.

By integrating IO-Link with PROFINET, manufacturers can achieve enhanced data exchange capabilities, real-time diagnostics, and simplified device configuration. This integration allows for greater flexibility in adapting to changing production requirements while minimizing downtime during maintenance or reconfiguration processes.

Furthermore, IO-Link to PROFINET integration provides manufacturers with valuable insights into their operations through comprehensive data collection and analysis. This facilitates informed decision-making regarding process optimization, predictive maintenance planning, and overall equipment effectiveness (OEE) improvements.

Click io link to profinet.

Conclusion

In conclusion, automation integrators are instrumental in driving efficiency and productivity within the manufacturing process. Through their expertise in leveraging advanced technologies like robotics and AI-driven systems along with partnerships with leading providers such as Solidot Electronic Technology; businesses can unlock new levels of operational excellence.

The adoption of emerging trends like IO-Link to PROFINET integration further empowers manufacturers by providing them with increased connectivity options and actionable insights derived from comprehensive data analysis. As industries continue to embrace automation on a larger scale, partnering with skilled automation integrators becomes essential for organizations aiming to stay ahead of the curve in today’s competitive business landscape.